Contact Information

Henan Road King Electromechanical Manufacturing Co., Ltd.

After Sales Service Hotline:

Phone:+86-377-63650816

Mobile:tel:+8613303776917

E-mail:sales001@roadkingem.com

Address: Lihe Industrial Park, Wancheng District, Nanyang City, Henan Province

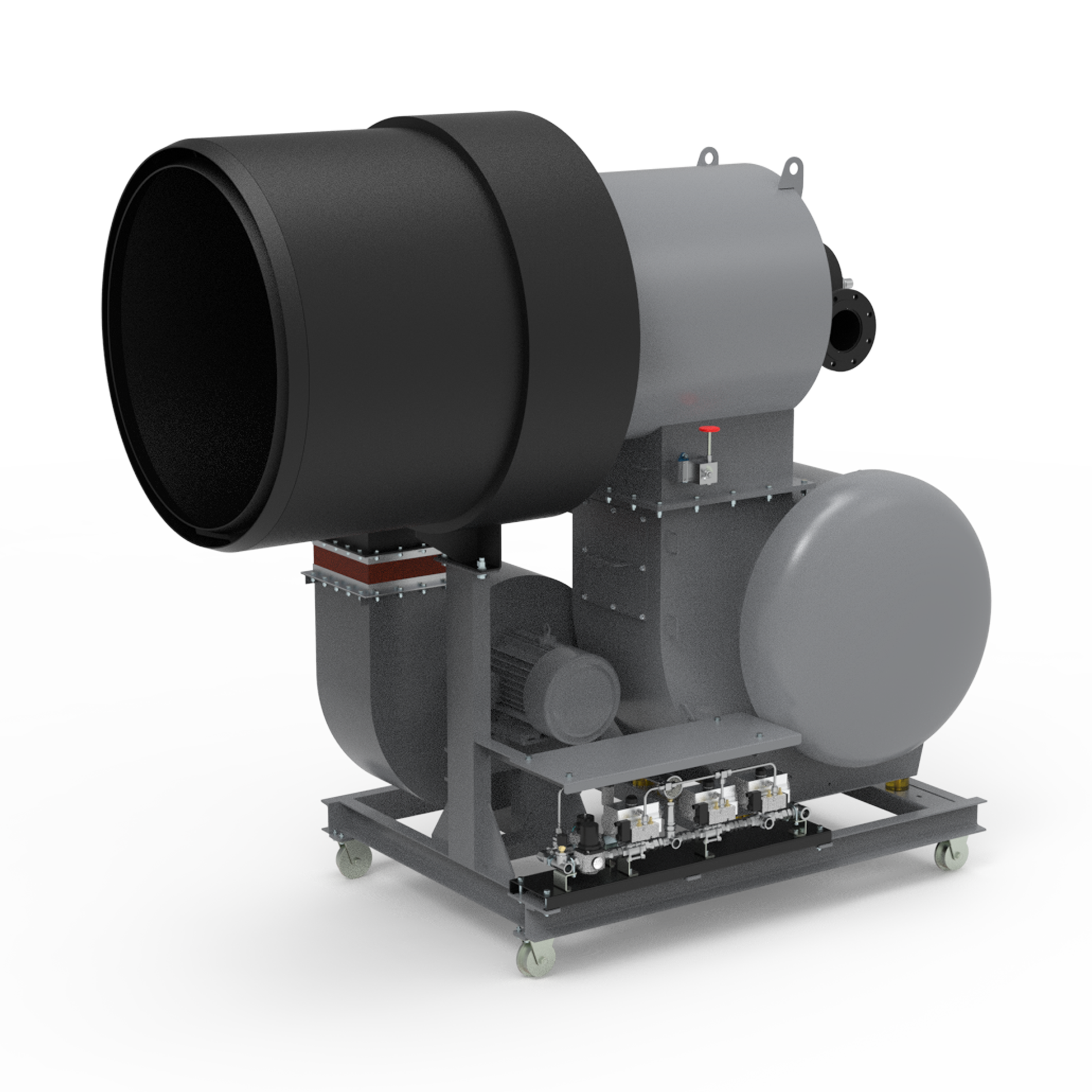

MFR Rotary Pulverized Coal Burner

MFR rotary pulverized coal burner is a new generation of heating device developed by our company on the basis of absorbing various specialties. It is an ideal supporting energy-saving equipment for municipal companies and highway asphalt mixture mixers, and is also widely used in various industrial furnaces.

- Descriptions

-

MFR rotary pulverized coal burner is a new generation of heating device developed by our company on the basis of absorbing various specialties. It is an ideal supporting energy-saving equipment for municipal companies and highway asphalt mixture mixers, and is also widely used in various industrial furnaces.

Most of the original asphalt mixture mixing equipment uses diesel or heavy oil as fuel to heat the aggregate. However, with the rising energy prices and the increasingly fierce market competition, fuel has gradually become the bottleneck to reduce the cost of asphalt mixture. So many construction units have changed the original fuel burner to pulverized coal burner to reduce production costs. However, these old-fashioned pulverized coal burners have four serious deficiencies in the use process.

1. Furnace slagging is serious and cleaning is very inconvenient.

2, the thermal efficiency is too low, the waste of coal powder is large.

3. Insufficient combustion of pulverized coal results in a large amount of pulverized coal contained in the recovered powder and cannot be used.

4, the burner failure rate is high and the service life is short, especially the fire nozzle needs to be replaced once every 15-30 days, which seriously affects the normal progress of the user's construction period.

Based on the above situation, our company invited relevant experts to participate in research and development and cooperate with large refractory factories to improve the burner from the following aspects.

1. According to the principle knowledge of aerodynamics and fluid mechanics and the combustion mechanism of pulverized coal under different coal quality, particle size, temperature and concentration, the spatial size of the combustion chamber, the structure of the air duct and the coal duct are reasonably improved. The pulverized coal is evenly mixed and completely burned in the combustion chamber, and the advantages of high flame temperature, fierce firepower, coal saving, and no pollution to the environment.

2. According to the special working condition that the burner is turned on in the morning and stopped at night, our company has funded and successfully developed high-performance refractory bricks adapted to this special working condition through many experiments by refractory manufacturers. The service life is 3-6 times that of similar products.

3. In order to reduce labor intensity, we divide the burner host into a fixed part and a rotating part, so that maintenance is more convenient.

4, can be 24 hours of continuous production, no need to clean slag every day.

This new type of burner is currently a relatively advanced pulverized coal combustion and heating device in China. It can be used in conjunction with fixed or mobile asphalt mixers ranging from 10 tons to 320 tons. The coal consumption per ton of asphalt mixture for coal-fired powder is about 10kg, and the oil consumption per ton of asphalt pellets for oil burning is about 7kg. If oil burning is changed to pulverized coal burning, the production cost will be greatly reduced and the economic benefits will be significantly improved. Therefore, this product is a rare energy-saving and efficiency-increasing equipment in the construction of municipal highway projects.

Product model and production volume comparison table

Model

Model

Installed power (kw)

Total power(kw)

Rated coal quantity (kg/h)

Rated coal powder

consumption (kg/h)

Mixer output (t/h)

Asphaltplant capacily(t/h)

material temperature control

Mixture temperature control

MFR300 16.95 300 15-20 130 ℃ ~ 180 ℃ MFR500 31.25 450 25-40 MFR1000 41.25 1000 70-85 MFR1500 73.75 1500 100-125 MFR2000 80.25 2000 140-170 MFR2500 105.25 2500 160-200 MFR3000 138.45 2860 200-250 MFR4000 194.95 3660 280-320 MFR5000 254.95 4500 360-400 Note: If there is any change due to product technology update and specific parameters, it is subject to change without notice.

Burner configuration

Model

Model

Host

Main body

pulverized coal machine

Coal pulverizer

Fuel igniter

Oil ignition

Power distribution cabinet

Controlcabinet

MFR300 LTZ30 FMJ30 RYDH

PD30 MFR500 LTZ40 FMJ40 PD40 MFR1000 LTZ80 FMJ80 PD80 MFR1500 LTZ120 FMJ120 PD120 MFR2000 LTZ160 FMJ80 FMJ80 PD160 MFR2500 LTZ200 FMJ120 FMJ80 PD160 MFR3000 LTZ240 FMJ120 FMJ120 PD240 MFR4000 LTZ320 FMJ120 FMJ120 FMJ120 PD320 MFR5000 LTZ400 FMJ150 FMJ150 FMJ150 PD400 Fuel Requirements

1. The oil used for fuel igniter is 0# diesel oil

2. Coal quality requirements: bituminous coal

(1) Calorific value ≥ 25kJ

(2) Volatile ≥ 25%

(3) Ash content 8 ~ 10%

(4) Total moisture 3-4%

(5) Total sulfur content ≤ 1%

(6) Particle size ≤ 20mm

Key words:

Message consultation

Related Products