Contact Information

Henan Road King Electromechanical Manufacturing Co., Ltd.

After Sales Service Hotline:

Phone:+86-377-63650816

Mobile:tel:+8613303776917

E-mail:sales001@roadkingem.com

Address: Lihe Industrial Park, Wancheng District, Nanyang City, Henan Province

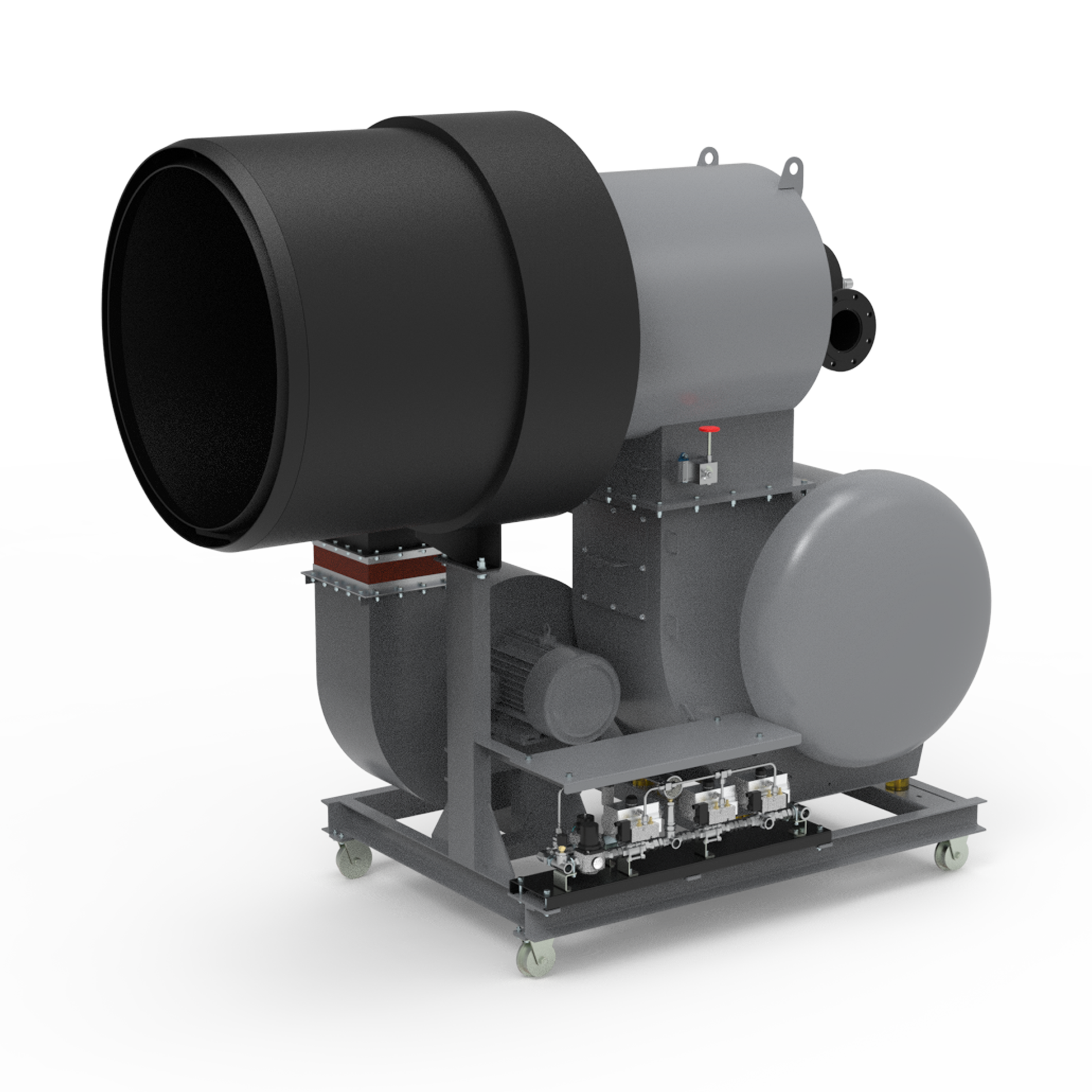

LCM series asphalt plant dedicated oil and gas burner

The LCM series kerosene, gas, and coal-fired burner is suitable for asphalt plant drying drum processes. Its ability to use coal, oil, and gas as fuel ensures both stability and economy, making it a smart choice for asphalt plant burners.

- Descriptions

-

- Suitable for asphalt plant drying drum processes, the burner can use coal, oil, and gas as fuel;

- Based on the existing technical accumulation of coal combustion, combined with oil and gas combustion technology, the newly developed burner can perform coal powder combustion, oil/gas combustion, and mixed combustion of the two fuels;

- Four combinations of coal powder, kerosene, coal gas, and kerosene gas are available. Coal, oil, and gas combustion do not reduce the combustion performance of the original fuels;

- Coal powder, oil, and gas burners are all automatically controlled, with one-button start/stop, remote monitoring, and fault alarm and diagnostic functions;

- Based on the technical characteristics of coal powder combustion, through staged fuel combustion and staged air supply, more complete and stable coal powder combustion is achieved;

- The newly designed flame tube adopts a three-stage air supply structure. The primary air duct separates the high-concentration air-powder mixture, the secondary air is a high-intensity swirl air, which swirls the coal powder into the central recirculation zone, where it mixes thoroughly with the internal air, effectively preventing the coal powder from spreading outward too quickly. The tertiary air is a straight-through air, providing sufficient air for coal powder combustion, ensuring complete combustion. A cooling air duct is set on the outside of the flame tube to reduce the flame tube temperature and improve its service life;

- The self-developed coal powder feeding and metering system can achieve a higher coal powder combustion adjustment ratio, and has the functions of instantaneous coal powder flow rate and cumulative usage, and can realize two control modes of frequency control and quantitative control of coal powder supply, achieving the purpose of precise control of coal consumption;

- The enclosed coal powder storage tank is isolated from the outside atmosphere under normal conditions, and is equipped with a explosion-proof door, safety valve, manhole, silo top dust collector, level detection, temperature detection, cone-type arch breaker, and nitrogen protection system, etc. The coal powder tank intelligent control system can realize one-button start/stop of powdering, intelligently monitors the temperature and level in the tank, realizes the automatic nitrogen protection function of the system, and the unique arch-breaking structure design ensures continuous and stable coal powder supply, providing multi-faceted protection for safe and stable production;

- The automatic nitrogen supply device is designed and developed according to the nitrogen protection process of the coal powder tank, with a large capacity of nitrogen generation and storage, providing sufficient nitrogen for the safety protection of the coal powder tank;

- The oil type uses advanced low-pressure medium atomizing spray guns for complete and efficient oil combustion, saving energy and protecting the environment;

- The gas type uses tubular fan-shaped nozzles for thorough mixing and high combustion efficiency;

- High-voltage electronic ignition, independent gas (propane, acetylene, liquefied gas) ignition guns, automatic ignition;

- Intelligent electronic proportional adjustment of fuel and air volume, frequency conversion automatic control, high control and adjustment accuracy, more complete combustion;

型号

Model

LCM1000YQ

LCM1500YQ

LCM2000YQ

LCM3000YQ

LCM4000YQ

LCM5000YQ

Maximum Output Power (MW)

Max heating out

7

10.5

14

21

26.5

33

Maximum Coal Consumption (Kg/h)

Max coal consumption

930

1400

1860

2800

3530

4400

Maximum Oil Consumption (Kg/h)

Max oil consumption

630

940

1260

1890

2380

2970

Maximum Gas Consumption (NM3/h)

Max gas consumption

680

1020

1360

2040

2580

3210

Fan Power

(KW)

Fan power

7.5

15

15

22

30

37

Coal Powder Conveyor Power (KW)

Coal powder conveyor power

15

15

18.5

18.5

22

22

Coal Powder Feeder Power (KW)

Coal powder feeder power

0.55×2

0.55×2

0.75×2

0.75×2

1.5×2

1.5×2

Oil Pump Power

(KW)

Oil pump power

2.2

2.2

2.2

3

4

4

Compressed Air Consumption (NM3/min)

Compressed air consumption

2.5

2.5

3.2

4

4

4

Gas train

Diameter

Gas train diameter

DN65

DN65

DN80

DN100

DN125

DN125

Matched Asphalt Mixing Plant Output (T/h)

Matched asphalt mixing plant

80

(1000 type)

120

(1500 type)

160

(2000 type)

240

(3000 type)

320

(4000 type)

400

(5000 type)

Regulation Ratio

Regulation ratio

1:8 (Oil mode/Gas mode) Oil mode/Gas mode

1:4 (Coal powder mode) Coal powder mode

Compressed Air Pressure

Compressed air pressure

≥0.6 MPa

Oil Supply Pressure

Oil supply pressure

≤0.03 MPa

Gas Supply Pressure

Gas supply pressure

45-55 KPa

Control Mode

Control mode

Electronic intelligent regulation, frequency conversion automatic control

Electronic intelligent regulation, automatic control by frequency converter

Ignition method

Ignition mode

High voltage electronic automatic ignition, independent gas ignition gun

High voltage electronic automatic ignition, independent gas ignition gun

Ignition gas

Ignition gas

Liquefied petroleum gas, propane, acetylene

LPG, Propane, Acetylene

Applicable fuel

Applicable fuel types

Coal powder, natural gas, diesel, heavy oil, residual oil

Coal Powder, Natural Gas, Diesel, Heavy Oil, Residual Oil

- Suitable for asphalt plant drying drum processes, the burner can use coal, oil, and gas as fuel;

Key words:

Message consultation

Related Products